Engineering Services

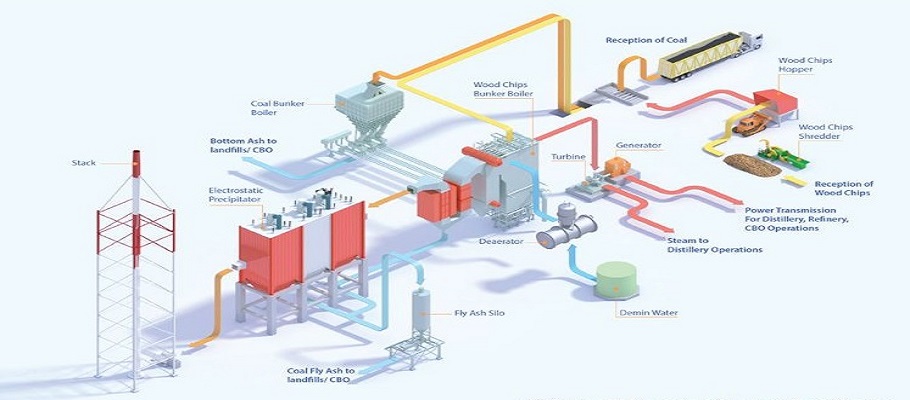

Design and Engineering of Thermal Power Plants has been our core expertise. We can design & engineer the entire power plant upto 100 MW capacities covering almost all types of fuels such as solid, liquid and gaseous involving boiler plants with steam turbines. We offer services ranging from conceptualization of power plant including evaluation of HMBD’s for most efficient power cycle selection to plant commissioning. We have expertise to handle all disciplines of power plant engineering comprising of Process, Mechanical, Electrical, C & I and Civil etc.

While we focused on technology & most techno-economic performance of the plant, we also take into consideration the environmental protection & sustainability, plant safety along with ease of operation & maintenance.

The various services we offer under engineering:

1-Pre - Feasibility Study:

-

Establishing the exact requirement of the customer in terms of steam, power etc.

-

Collection & review of all applied data

-

Development of the power plant concept and technical alternatives

-

Determining the optimal technical solution in relation to plant output, thermal efficiency and specific generation costs, environmental compliance and land usage

-

Computation of power plant investment and operation costs

- Preparation of general site layout drawings

- Execution of the Pre-Feasibility Study

- Preparation of the Pre-Feasibility Study Report

2- Detailed Project Report (DPR) Preparation:

- Need for the Project

- Project Approval & Clearances

- Project Details – Technical

- Environmental aspects

- Identifying project risks & developing a mitigation plan to tackle

- Project Financials

- Operating Framework

- Project Execution Plan

- Master Project Schedule

3- Basic Engineering:

Basic Engineering, Selection & preparation of tender specifications of equipment for the Power Plant considering appropriate steam and power balance, operating economics and capital costs covering all the equipment/system with schematic design, Electrical SLDs, Plant Layout Drawings etc.

- Turbine and its auxiliaries

- Boiler and its auxiliaries

- Fuel handling system

- Flue gas desulphurization unit (FGD)

- Ash handling system

- Preparation of Overall Plant Layout

- Building general arrangements

- Preparation of Heat & Mass Balance Diagram(HMBD)

- Preparation of Water Balance Diagram (WBD)

- Equipment sizing calculations

- Piping system

- Electrical system

- Instrumentation system

- Compressed air system

- Other balance of plant (BOP) systems

- Preparation of Detailed Piping & Instrumentation Diagram (P&ID) & Process Flow Diagram (PFD)

- Operation & control philosophy

- Compilation of auxiliary power consumption list

- Data sheets for all equipment

4- Procurement Assistance:

We offer complete assistance in procurement which covers the following activities:

- Preparation of prequalification criteria for suppliers

- Floating the detailed enquiries (tender/RFQ)

- Techno – Commercial evaluations of bids

- Providing technical clarifications to the bidders if any

- Assist customer in negotiations with bidders

- Purchase recommendations

- Preparation of contract document

5- Detailed Engineering:

Detailed engineering includes the extraction of all the essential information from all the basic engineering drawings and calculations to provide the exact drawings in detail for all Productsion, fabrication & erection items and in turn the details of entire project along with the precise bill of quantities and specifications for each of the equipment.

- Detailed design & drawings of civil foundation, building construction, evacuation etc.

- General arrangements drawings of various plant buildings, floors etc.

- Detailed plant layout drawing

- Piping design and drawings including piping material specifications, layout drawings, isometrics, stress analysis, bill of materials, pipe supports etc.

- Detailed design of electrical system including equipment, switchgear, switchyard, transformers layouts, earthing system design & layouts, detailed load list, feeders list for switchgears, MCC etc, cable schedule & sizing, cabling layouts, illumination system layout, protection system, relay settings etc.

- C&I system includes DCS/PLC system configuration, I/O list, logic diagrams, closed/open loop schemes, hook-up drawings etc.

- Review of vendor drawings& datasheets for comments/approval

- Preparation of as built drawings and O&M manuals